1. Spacecraft and Satellite Development

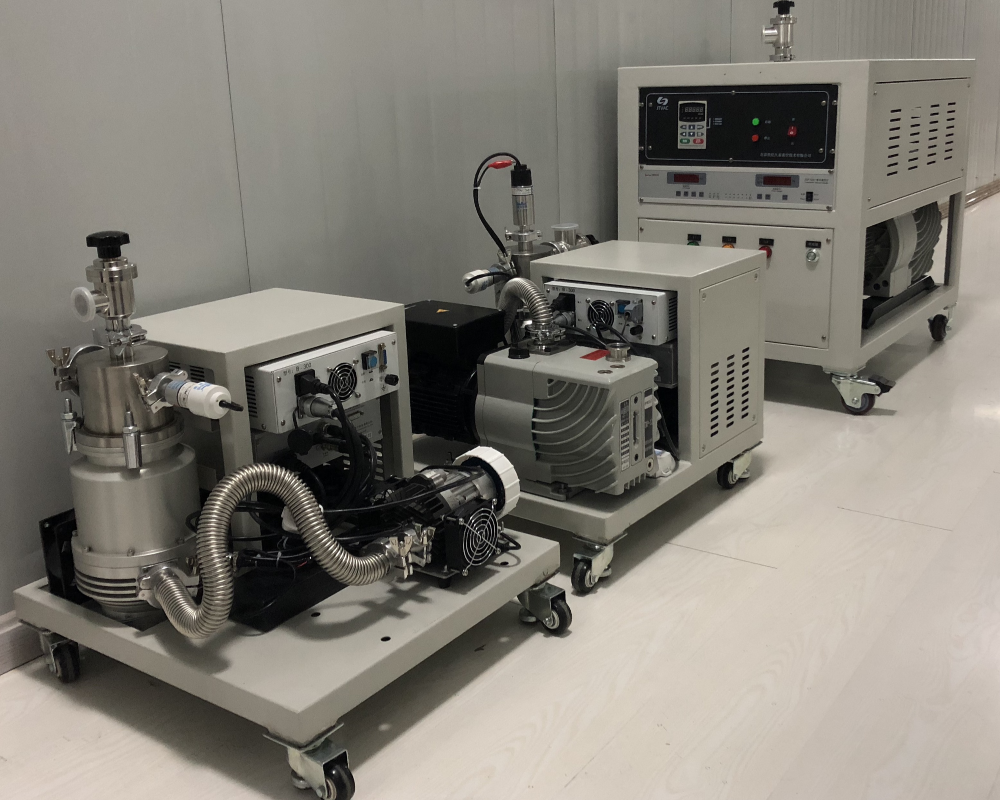

Vacuum Environment Simulation

Turbo molecular pumps are widely used in ground-based vacuum simulation chambers to simulate the high vacuum environment of outer space (10⁻⁶ to 10⁻⁹ torr), testing the performance and reliability of spacecraft. Application scenarios include testing the vacuum adaptability of satellites, spacecraft hulls, and electronic components.Propulsion System Testing

In the development of high-efficiency propulsion systems such as ion thrusters and electric arc thrusters, turbo molecular pumps are used to maintain ultra-high vacuum in the test chambers, ensuring the flow and reaction of propellants (such as xenon gas) in the vacuum.Sensor and Measurement Equipment Development

Spaceborne sensors (such as infrared detectors and spectrometers) require calibration in vacuum environments during manufacturing and testing. Turbo molecular pumps provide a contamination-free vacuum environment to ensure high precision of the equipment.

2. Space Station and Detector Technologies

Manned Spaceflight Technology Support

Turbo molecular pumps are used in the development of air purification and regeneration systems for manned spacecraft, ensuring the stability of the internal gas composition.Performance Validation of Detector Components

Deep space probes (such as Mars rovers and lunar probes) need to undergo vacuum simulation tests in chambers before launch to validate their endurance. Turbo molecular pumps help precisely simulate the vacuum conditions of outer space.Optical and Communication Equipment

Turbo molecular pumps support the manufacturing and testing of space optical equipment (such as telescope lenses) and communication systems, providing a clean vacuum environment to prevent particles from affecting the equipment's performance.

3. Aerospace Materials Manufacturing

Vacuum Melting of High-Performance Materials

Turbo molecular pumps are used to produce high-performance alloys and composite materials that are resistant to high temperatures and corrosion, ensuring a clean environment during the melting process and improving material properties.Coatings and Thin Film Production

In the preparation of thermal barrier coatings, anti-reflection coatings, and functional films, turbo molecular pumps are used in deposition processes to ensure the uniformity and adhesion of coatings, providing surface protection for spacecraft.Ceramic and Composite Materials Processing

Turbo molecular pumps support the fabrication of high-strength ceramics and composite materials, widely used in the manufacturing of spacecraft heat shields, structural components, and other parts.

4. Spacecraft Launch and Operation Support

Launch Environment Preparation

During spacecraft assembly and launch preparations, turbo molecular pumps are used to evacuate equipment interiors and fuel delivery systems, ensuring the reliability of the launch process.Orbital Operations and Maintenance

Turbo molecular pumps are integrated into orbital equipment to maintain the vacuum environment of critical components, such as thermal control systems and sealed cabins.

5. Scientific Research and Experiment Support

Space Science Experiments

Turbo molecular pumps are used in space microgravity experimental devices to ensure ultra-high vacuum conditions inside the experimental setup, studying the effects of microgravity on materials, living organisms, and chemical reactions.Analysis of Celestial Samples

In the analysis of lunar, Mars, and other celestial body samples, turbo molecular pumps maintain ultra-high vacuum conditions in sample transfer and analysis equipment, reducing contamination and interference with research results.Gas Composition Analysis

In extraterrestrial atmospheric analysis, turbo molecular pumps are integrated into spacecraft mass spectrometers to study the composition and distribution of gases in outer space.

6. Aircraft Testing and Maintenance

High-Altitude Aircraft Testing

Turbo molecular pumps are used in high-altitude aircraft (such as drones and high-altitude balloons) for pressure testing, simulating the thin atmospheric conditions, and evaluating the performance of the aircraft.Turbo Engine Vacuum Support

In the research and testing of aircraft engines, turbo molecular pumps help analyze the gas flow and performance in combustion chambers and thrusters.

中文版

中文版 English

English