1. What is a magnetic levitation molecular pump

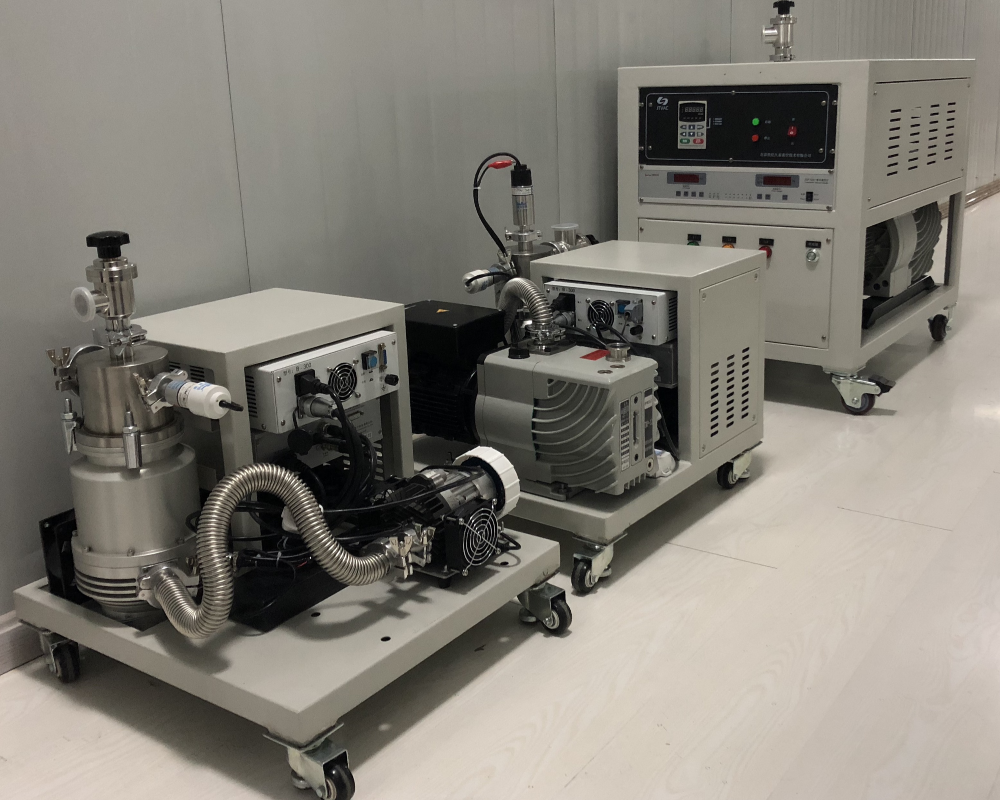

A magnetic levitation molecular pump is a vacuum pump that uses magnetic levitation technology to suspend the rotor in a magnetic field. It extracts gas molecules from the vacuum chamber step by step through molecular collisions between the high-speed rotating rotor and stator. Due to the lack of mechanical contact, the magnetic levitation molecular pump has the characteristics of friction-free, pollution-free, low maintenance and high reliability, and is widely used in semiconductor manufacturing, optical coating, scientific research experiments and other fields that require ultra-high vacuum.

2. What are the advantages of magnetic levitation molecular pumps

(1)Friction-free operation: The rotor is suspended in the magnetic field, without mechanical contact, reducing wear and extending service life.

(2)Ultra-clean vacuum: no oil lubrication, no particle or oil vapor pollution, suitable for occasions with high cleanliness requirements.

(3)Low maintenance cost: no need to replace bearings or lubricating oil, reducing maintenance frequency and cost.

(4)Low vibration and noise: smooth operation, friendly to precision applications.

(5)High speed performance: higher speed, faster pumping speed, lower limit pressure.

(6)High reliability: real-time monitoring of operating status, strong stability.

(7)Environmental protection: no lubricating oil pollution, more environmentally friendly.

3. Selection Guide for Magnetic Levitation Molecular Pumps

(1)Pumping speed requirements

Determine the pumping speed range: Select the appropriate pumping speed (unit: L/s) according to the application requirements.

Small laboratory equipment: The pumping speed is generally 50-300 L/s.

Semiconductor equipment or industrial use: A higher pumping speed is required, such as 500-3000 L/s.

Gas type: For light gases (such as hydrogen, helium) or high molecular weight gases, a suitable molecular pump must be selected.

(2)Ultimate vacuum requirements

Application target pressure:

Ultra-high vacuum application: The ultimate pressure must reach 10⁻⁷ Pa or lower.

Ordinary high vacuum: An ultimate pressure of about 10⁻⁴ Pa can meet the requirements.

Residual gas requirements: Select an oil-free or low-pollution magnetic levitation molecular pump to avoid affecting the vacuum purity.

(3) Chamber volume and pumping speed matching

Volume size calculation: Determine the chamber volume and pumping speed matching time to ensure that the pump can reach the target vacuum within the required time.

(4)Gas flow

Ensure that the pump can withstand the gas flow generated in the process.

Corrosive or special gas treatment: Select a magnetic levitation molecular pump with corrosion-resistant design.

(5)Structure and installation method

Flange interface type: Select a suitable flange interface (ISO-KF, ISO-F, CF).

Installation direction: Confirm whether the pump can be installed in a vertical or horizontal direction.

Cooling method: Air cooling or water cooling can be selected, depending on environmental conditions.

中文版

中文版 English

English