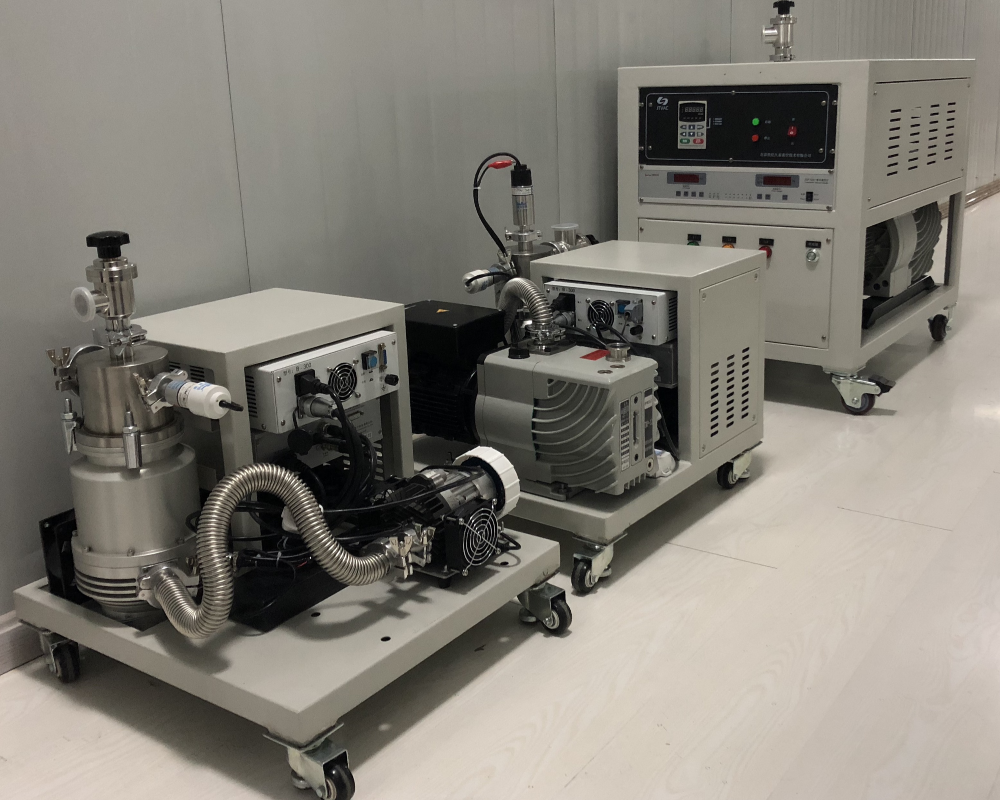

1. Introduction to JT series oil-lubricated molecular pumps

JTFB-compound molecular pumps are composed of turbomolecular pumps and disc traction pumps. They have the characteristics of high pumping speed and high compression ratio when the turbomolecular pump is in molecular flow, and high pumping speed and high compression ratio when the traction pump is in high pressure, which expands the application range of molecular pumps. The compound molecular pump has no selectivity and no memory effect on the pumped gas. Because it has a high compression ratio for gases with large molecular weight, the pump does not need a cold trap and an oil baffle to obtain clean high vacuum and ultra-high vacuum. It is widely used in various fields of electronics, metallurgy, chemical industry, scientific research and vacuum technology.

This molecular pump has no selectivity and no memory effect on the pumped gas. Because it has a high compression ratio for gases with large molecular weight, the pump does not need a cold trap and an oil baffle to obtain clean high vacuum and ultra-high vacuum. It is widely used in various fields of electronics, metallurgy, chemical industry, scientific research and vacuum technology.

JT compound molecular pump adopts imported precision bearing support, and the cooling method is water cooling or air cooling. The working environment temperature of air-cooled pump must be lower than 28℃. The rotor is dynamically balanced after the whole unit, and the operation is stable and reliable. The motor is a squirrel cage three-phase motor, and the bearing lubrication adopts tapered hole shaft self-priming oil lubrication, which is simple and reliable, but it also determines that the molecular pump can only be installed vertically.

2. Oil-lubricated molecular pump selection guide

(1) Pumping speed requirements

Clearly define the pumping speed range:

Small equipment: 50-300 L/s, used for laboratory analytical instruments.

Medium-sized system: 300-1500 L/s, suitable for industrial vacuum applications.

Large equipment: >1500 L/s, used for large vacuum systems such as vacuum coating or nuclear industry equipment.

Gas type: Oil-lubricated molecular pumps have good performance for light gases (such as hydrogen and helium) and heavy gases (such as argon).

(2) Ultimate vacuum degree

Standard application: can reach 10⁻⁶ to 10⁻⁸ Pa, suitable for most processes with high vacuum requirements.

Ultra-high vacuum requirements: select models with special designs to ensure that lower pressure levels are achieved.

(3) Chamber volume and pumping time

Determine the chamber volume and target vacuum degree, calculate the pumping time of the pump, and ensure that the model meets the process requirements.

Empirical formula: Pumping time = (chamber volume × ln(P1/P2)) / pumping speed.

(4) Process compatibility

Corrosion resistance: suitable for processes that handle non-corrosive or slightly corrosive gases.

Water vapor handling capacity: Some models have high water vapor throughput capacity, suitable for processes with more moisture.

(5) Operating environment and installation

Cooling method: Most oil-lubricated molecular pumps use water cooling or air cooling. Select the appropriate cooling method according to the operating environment:

Water cooling: suitable for high temperature environments or continuous operation processes.

Air cooling: Suitable for small and medium-sized equipment or intermittent operation scenarios.

Installation direction: Make sure the pump supports the required installation direction (such as vertical or horizontal installation).

(6) Use and maintenance

Maintenance frequency: Compared with grease-lubricated molecular pumps, oil-lubricated molecular pumps require regular replacement of lubricating oil and filter elements to maintain performance.

Standard maintenance cycle: Depending on the operating time and working conditions, it is recommended to check and replace the lubricating oil every 6-12 months.

Vacuum contamination protection: Regularly check the oil contamination to prevent oil deterioration due to process gas.

中文版

中文版 English

English