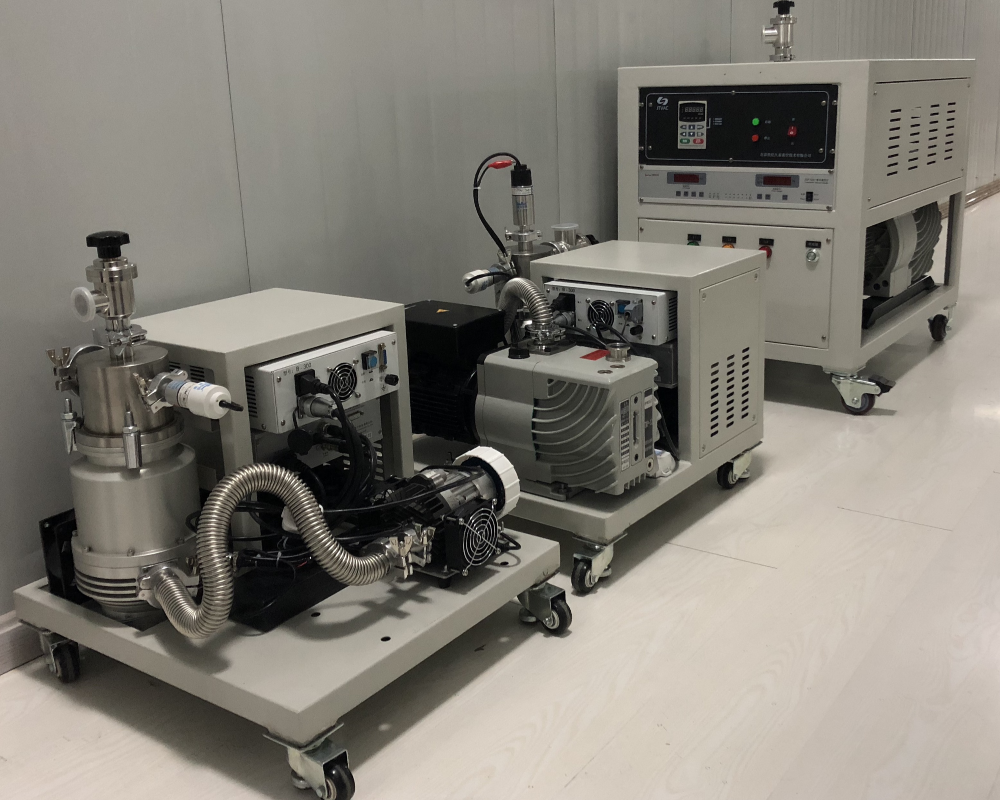

1. Introduction to JT series ultra-high vacuum units

Jiutai Vacuum ultra-high vacuum molecular pump series exhaust units are designed and manufactured to meet the needs of the vacuum application market. The whole machine is simple, beautiful, has excellent performance, is easy to operate and maintain. Our company can also make non-standard customization according to customer requirements to ensure quality and timely delivery.

The vacuum in the JT series ultra-high vacuum unit is obtained by molecular pump + mechanical pump. The vacuum degree of the equipment is better than 3*10-3Pa after the molecular pump is started to 400HZ; better than 5*10-4Pa within 30 minutes; the ultimate vacuum is 3*10-5Pa.

The unit is a movable table trolley structure, which can meet the needs of exhaust at different positions. In order to shorten the exhaust time and effectively improve work efficiency, the unit can be equipped with a pre-exhaust system, which can realize the exhaust process of changing workpieces, pre-exhaust, and high vacuum without stopping the molecular pump.

2. Ultra-high vacuum unit selection guide

(1) Pumping speed requirements

Target vacuum: Select the appropriate unit according to the actual process requirements:

Ultra-high vacuum:

10−6 to 10−8 Pa.

Ultra-high vacuum:

10−9 Pa or less, suitable for laboratory and scientific research applications.

Cavity volume and pumping time:

Calculate the cavity volume and pumping speed requirements to ensure that the unit can reach the target vacuum within the required time.

Empirical formula: Pumping time = (cavity volume × ln(P1/P2)) / pumping speed.

(2) Main configuration

Ultra-high vacuum units usually consist of a fore pump, a main pump (such as a turbomolecular pump or a magnetic levitation molecular pump), a vacuum valve and a control system.

Main pump type:

Turbomolecular pump: suitable for most ultra-high vacuum processes, economical and efficient.

Magnetic levitation molecular pump: oil-free, suitable for extremely high cleanliness and high-precision application scenarios.

Foreline pump selection:

Dry screw pump: oil-free design, suitable for clean environment.

Oil-sealed mechanical pump: economical solution, suitable for general industrial applications.

Vacuum valve:

Ultra-high vacuum gate valve or bellows valve is configured to ensure sealing performance.

Cooling method:

Select air cooling or water cooling system according to the design of the pump to ensure stable temperature of the equipment during continuous operation.

(3) Process compatibility

Gas type: Confirm the target gas type (such as inert gas, corrosive gas, etc.) to ensure the corrosion resistance of the pump material and seals.

Special requirements: If a large amount of water vapor or light gas needs to be processed, select a model with high throughput capacity or optimized design.

(4) System control and safety

Automatic control: Optional intelligent control system to achieve real-time monitoring and automatic adjustment of vacuum status.

Protection function: Ensure that it is equipped with anti-backflow device, overpressure protection and power protection function to prevent equipment damage or process contamination.

(5) Operating environment and installation space

Installation space: Reserve enough space according to equipment size and maintenance requirements.

Ambient temperature: Most units are suitable for temperatures between 5–40°C. Avoid operating at too high or too low a temperature.

Vibration and noise: For applications that are sensitive to vibration and noise, it is recommended to choose low-vibration and low-noise models (such as magnetic levitation molecular pumps).

中文版

中文版 English

English