The Evolution and Applications of Vacuum Technology

Introduction

Vacuum technology is a cornerstone of modern science and engineering, enabling breakthroughs in diverse fields ranging from semiconductor manufacturing to aerospace exploration. By creating and maintaining environments with pressures significantly lower than atmospheric pressure, vacuum technology facilitates processes that would otherwise be impossible.

This article explores the fundamentals of vacuum technology, its historical evolution, and its key applications in various industries.

What Is Vacuum Technology?

Vacuum technology involves the creation and maintenance of a vacuum—a space devoid of matter or where the pressure is significantly lower than atmospheric pressure. The degree of vacuum is measured in units such as torr, pascal (Pa), or bar. Vacuum levels are categorized into:

Rough Vacuum: 1 to 10⁵ Pa

Medium Vacuum: 10⁵ to 10⁻² Pa

High Vacuum: 10⁻² to 10⁻⁵ Pa

Ultra-High Vacuum (UHV): Below 10⁻⁵ Pa

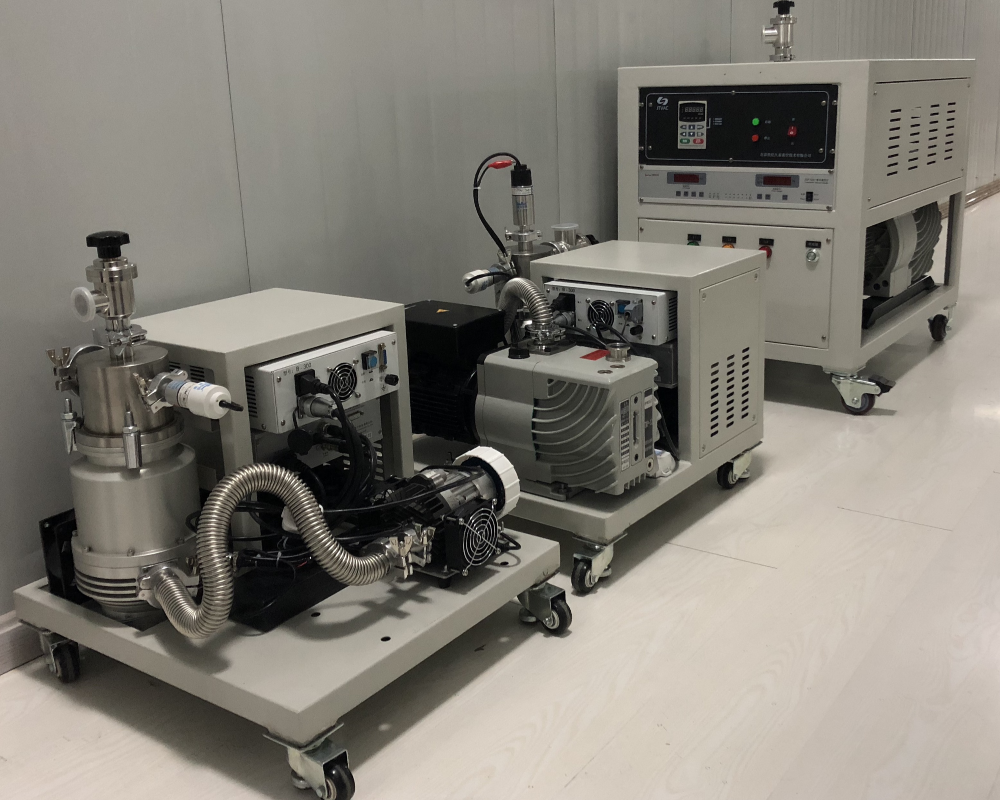

To achieve these vacuums, a combination of pumps, seals, and chambers is used. Common vacuum pumps include rotary vane pumps, roots pumps, turbo molecular pumps, and cryopumps.

Historical Development

The concept of vacuum dates back to ancient Greece, but it wasn’t until the 17th century that Evangelista Torricelli demonstrated the existence of vacuum using a mercury barometer. Subsequent developments by Blaise Pascal and Otto von Guericke laid the groundwork for modern vacuum technology.

With the advent of the 20th century, vacuum technology advanced rapidly, driven by the demands of scientific research and industrial applications. The development of high-vacuum pumps and materials capable of withstanding extreme conditions propelled industries such as electronics and space exploration.

Applications of Vacuum Technology

1. Semiconductor Manufacturing

Vacuum technology is indispensable in the production of semiconductors. Processes like chemical vapor deposition (CVD), physical vapor deposition (PVD), and plasma etching rely on controlled vacuum environments to ensure precision and quality. Turbo molecular pumps and cryopumps are commonly used to achieve the ultra-high vacuum levels required for these processes.

2. Aerospace and Space Exploration

In aerospace, vacuum chambers simulate the vacuum conditions of outer space, enabling the testing of satellites, spacecraft, and components. For instance, thermal vacuum chambers replicate the extreme temperatures and pressures experienced in orbit.

3. Scientific Research

Research in physics, chemistry, and material science heavily relies on vacuum technology. Particle accelerators, such as the Large Hadron Collider, operate under ultra-high vacuum conditions to reduce particle collisions with air molecules, ensuring precise experiments.

4. Industrial Manufacturing

Vacuum systems are essential in industries like metallurgy, where vacuum furnaces are used for heat treatment and material processing. Vacuum technology is also employed in the production of high-purity materials and coatings.

5. Medical and Pharmaceutical Applications

Vacuum technology is used in the freeze-drying of pharmaceuticals, sterilization processes, and the production of medical devices. It ensures contamination-free environments essential for these applications.

6. Renewable Energy

In solar panel manufacturing, vacuum deposition techniques are used to create thin-film photovoltaic cells. Additionally, vacuum technology plays a role in the production of batteries and fuel cells.

Challenges and Innovations

While vacuum technology has advanced significantly, challenges remain. Achieving and maintaining ultra-high vacuum levels requires meticulous design and maintenance. Issues like leaks, outgassing, and material limitations need constant attention.

Innovations in vacuum pump design, materials science, and monitoring technologies are addressing these challenges. For example, dry vacuum pumps have gained popularity due to their low maintenance and contamination-free operation.

Conclusion

Vacuum technology is a critical enabler of progress in science and industry. Its applications span an array of fields, driving innovation and shaping the future. As research and development continue, vacuum technology will undoubtedly play a pivotal role in addressing global challenges and unlocking new possibilities.

中文版

中文版 English

English